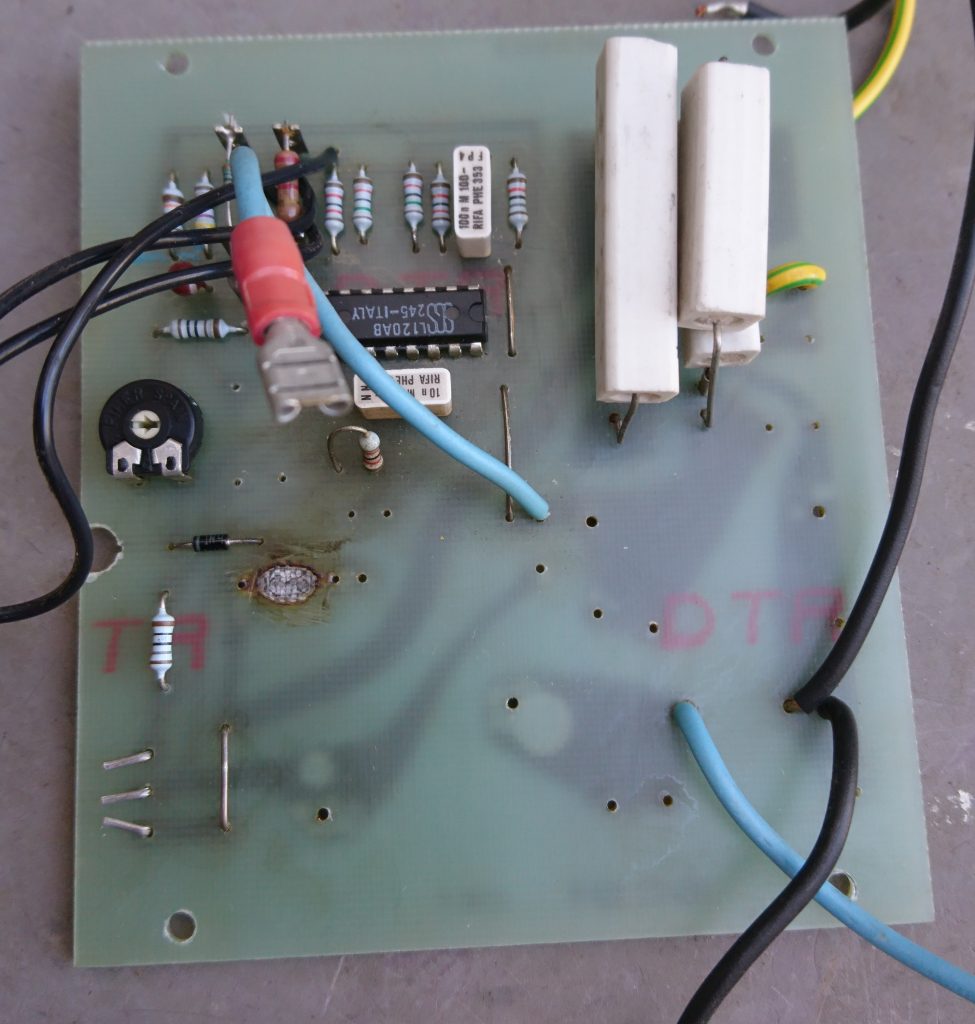

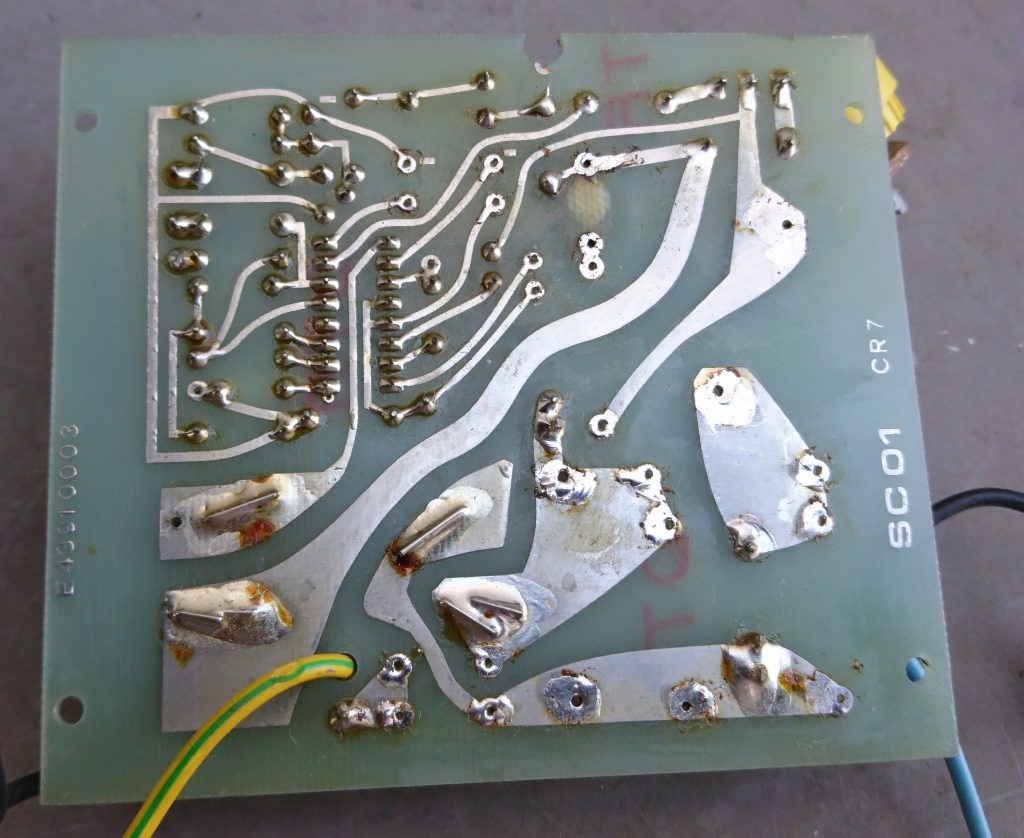

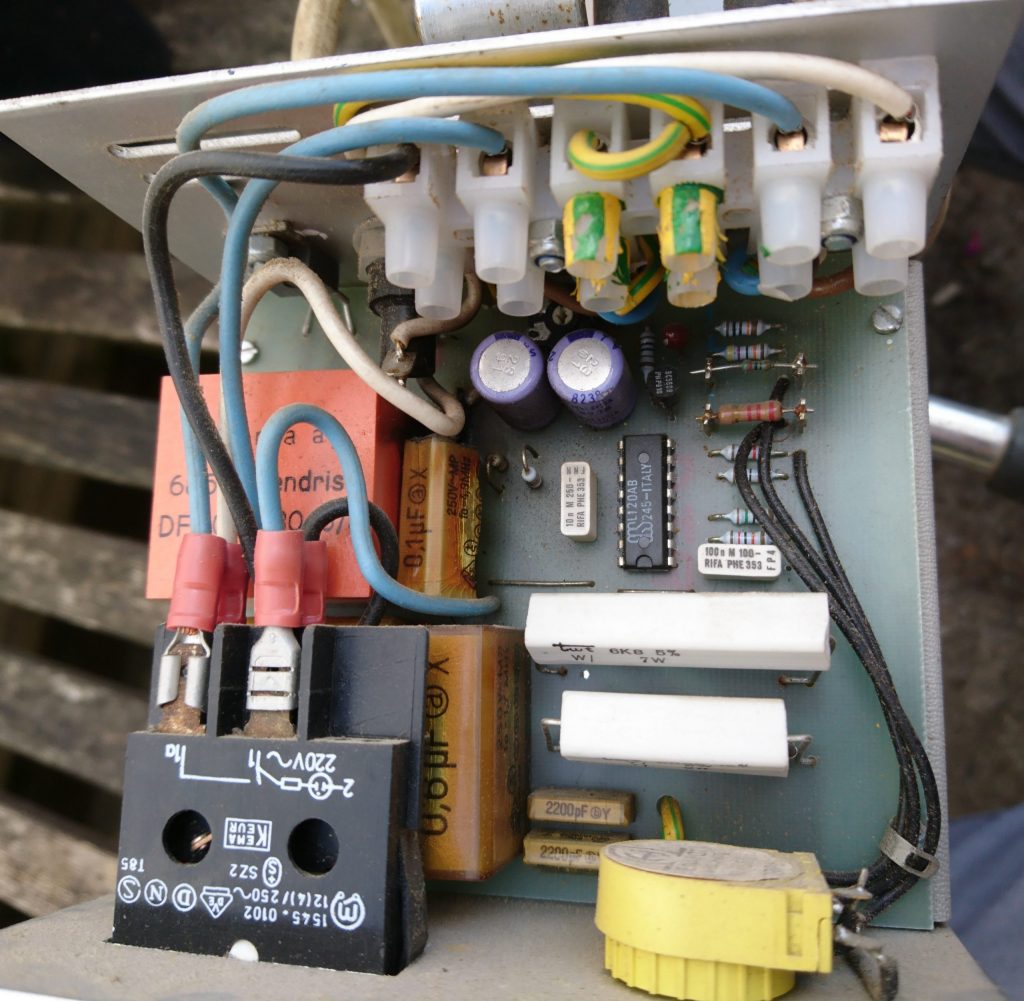

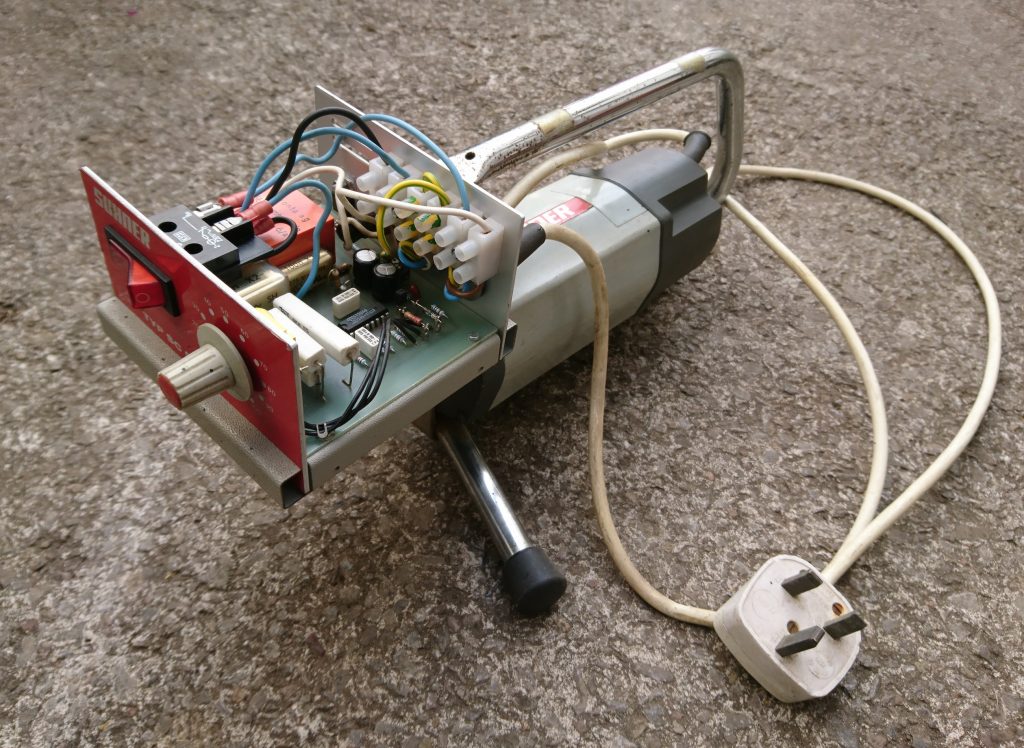

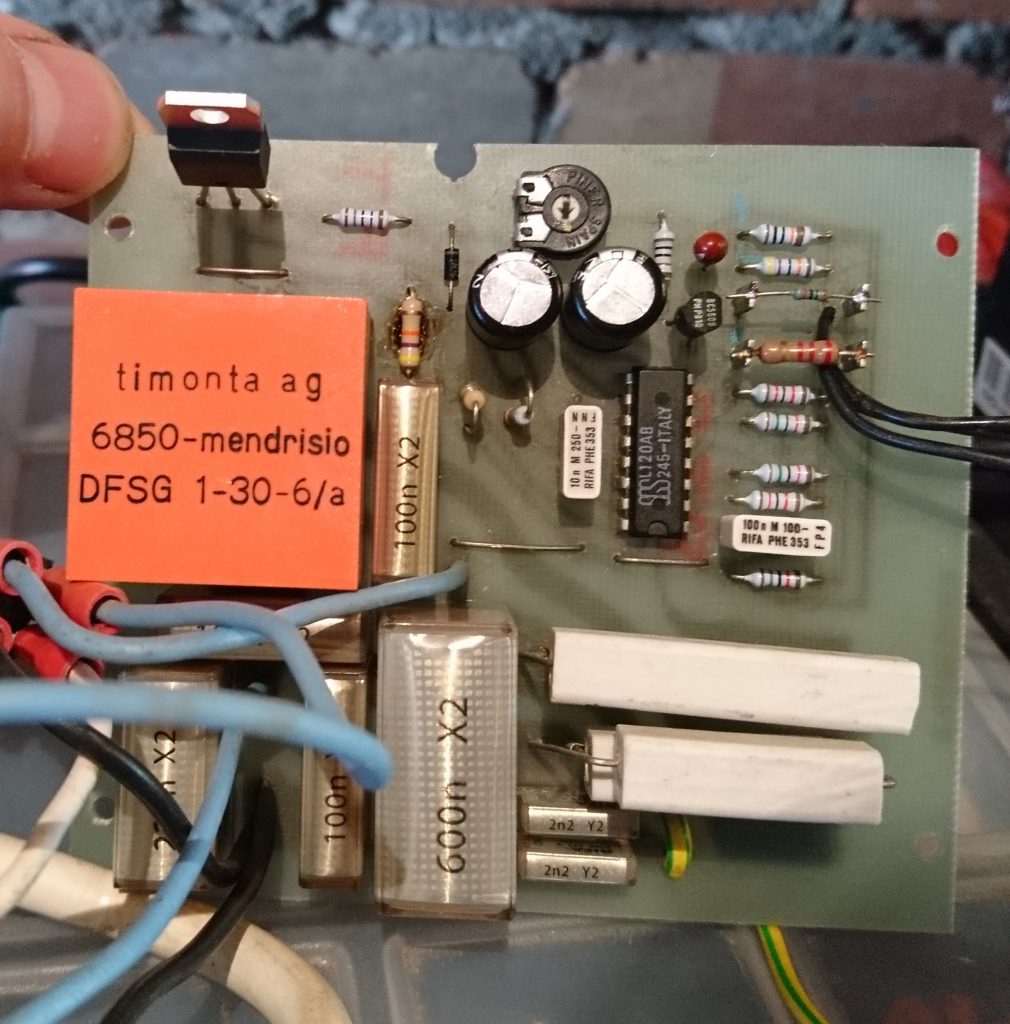

The following pictures show the new components and the completed board.

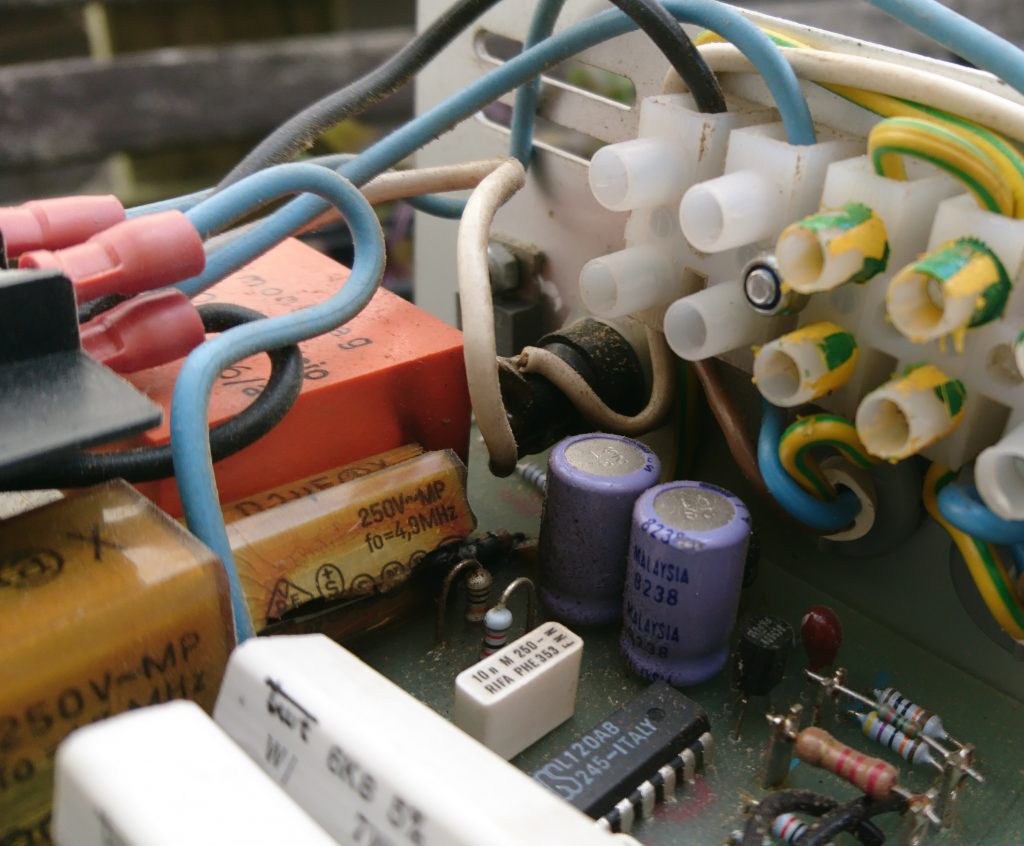

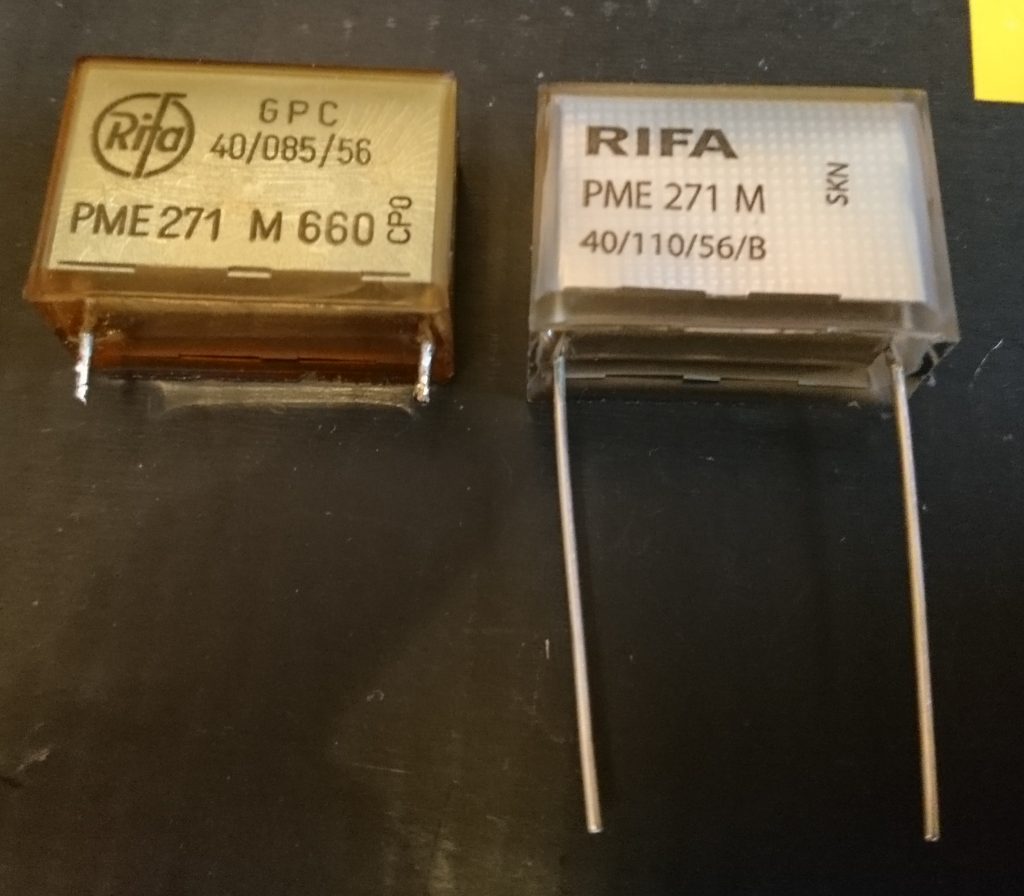

The above image shows the new and old Rifa capacitor. You can see the crazing and discolouring on the left hand side.

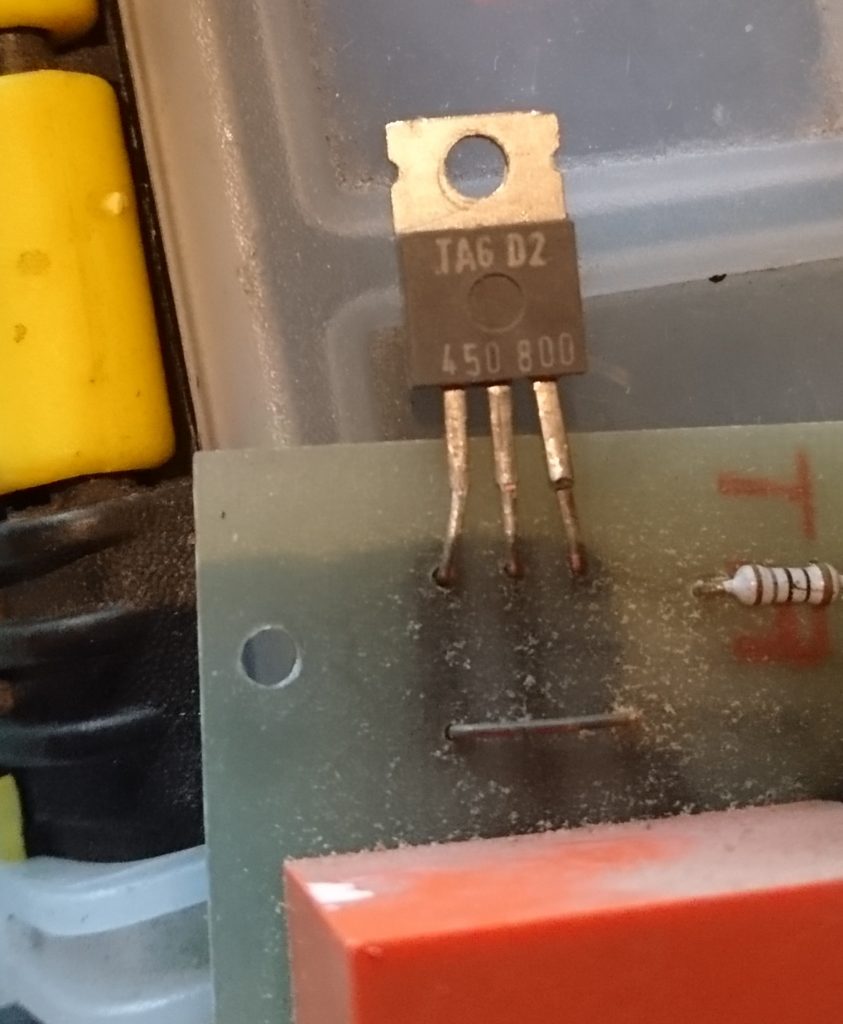

There was some difficulty in finding an alternative TRIAC. From the part numbers on the package, TAG D2 450 800 , I took a guess on the typical specifications as I could not find a vintage TAG Semiconductors parts catalogue. I used a ST BTA16-800CW with a blocking voltage of 800V and an RMS current of 16A.

The motor is now working well unloaded and is surprisingly loud at max speed (28,000 rpm).

Watch this space for a reverse engineered circuit diagram.